10 scientific facts about emulsifiers you didn’t know

Emulsifiers: Key Active Ingredients for Achieving Completely Combined Formulations

Emulsifiers play an essential function in developing stable blends of immiscible fluids, such as oil and water. Their distinct residential or commercial properties permit them to reduce surface stress, which is essential for uniformity in different formulas. Recognizing the differences between artificial and natural emulsifiers can influence product high quality substantially. As industries increasingly seek to improve structure and life span, the selection process for the best emulsifier ends up being extremely important. What factors should be thought about in this vital selection?

Understanding Emulsifiers: What They Are and How They Work

Emulsifiers may seem like an easy addition to formulas, they play a vital function in supporting blends of components that normally do not mix well, such as oil and water. These substances operate by minimizing surface area stress at the interface between immiscible liquids, allowing them to blend even more evenly. Emulsifiers consist of both hydrophilic (water-attracting) and lipophilic (oil-attracting) properties, which allow them to secure themselves at the border of both stages. By doing so, they develop a protective obstacle that protects against the beads of one liquid from integrating into bigger masses, thereby maintaining a stable solution. The performance of an emulsifier depends upon its molecular structure, which affects its capability to maintain mixes. In different applications, from foodstuff to cosmetics, emulsifiers guarantee a constant structure and look, improving both functionality and customer allure. Their relevance can not be overemphasized in accomplishing well-blended formulations.

Kinds of Emulsifiers: All-natural vs. Synthetic

Emulsifiers can be extensively categorized into 2 types: natural and artificial, each offering distinctive advantages and applications. Natural emulsifiers, stemmed from plant or animal sources, include casein, lecithin, and periodontal arabic (emulsifiers). These emulsifiers are commonly preferred in clean-label and natural items because of their minimal processing and biocompatibility. Their gentle nature makes them appropriate for delicate solutions, especially in food and cosmetics

On the various other hand, synthetic emulsifiers such as mono- and diglycerides, and polysorbates are made through chemical processes. They are typically utilized in commercial applications because of their stability and effectiveness in creating emulsions. Artificial emulsifiers usually exhibit remarkable efficiency in severe conditions, such as heats or differing pH levels. The choice between synthetic and all-natural emulsifiers greatly depends on the details formulation needs, regulatory factors to consider, and customer choices, influencing their reliable application in different sectors.

Features of Emulsifiers in Food and Aesthetic Formulations

The role of emulsifiers expands beyond simple stabilization; they are fundamental in accomplishing the preferred shelf, look, and structure life of food and cosmetic products. In food formulations, emulsifiers aid blend oil and water, creating smooth and consistent appearances necessary for sauces, dressings, and milk products. They minimize surface tension, improving the stability of emulsions, which protects against splitting up and prolongs freshness.

In cosmetics, emulsifiers assure that ingredients, such as oils and water, mix seamlessly, supplying a pleasant feeling and improving application. emulsifiers. They add to the item's thickness and spreadability, vital for creams, products, and creams. In addition, emulsifiers can envelop energetic ingredients, boosting their circulation and effectiveness in solutions. By regulating appearance and boosting sensory characteristics, emulsifiers play an important role in conference customer assumptions in both food and cosmetic markets, assuring products are not just enticing but likewise functionally effective

Picking the Right Emulsifier for Your Item

:max_bytes(150000):strip_icc()/eating-well-emulsifier-dressings-3021330094034a48961553c1a8aea356.jpg)

Additionally, the target application-- whether for food, cosmetics, or drugs-- will certainly affect the choice. Food-grade emulsifiers must conform with security guidelines, while cosmetic emulsifiers might call for skin compatibility. Examining factors such as HLB (Hydrophilic-Lipophilic Balance) helps in predicting emulsifier habits in specific formulas. Eventually, a detailed analysis of both functional requirements and regulative considerations is necessary to pick one of the most efficient emulsifier, ensuring the last item fulfills the preferred quality and security criteria.

Tips for Successful Emulsion Development and Stability

Accomplishing successful emulsion development and security needs careful interest to numerous critical factors. The selection of emulsifier plays a crucial duty; it must be suitable with the oil and water phases to guarantee efficient stablizing. Second, the proportion of oil to water should be balanced, as an improper ratio can result in instability. Third, the mixing procedure ought to be regulated; high shear blending can aid accomplish smaller droplet dimensions, enhancing stability.

Temperature additionally my website influences emulsion stability; preserving perfect temperature levels during formulation prevents early separation. Additionally, integrating stabilizers such as thickeners can further improve viscosity, minimizing the chance of stage splitting up. Carrying out complete security examinations after solution will certainly assist determine potential concerns, enabling for adjustments prior to final manufacturing. By adhering to these standards, formulators can achieve regular and dependable solutions that keep their desired properties over time.

Often Asked Concerns

Can Emulsifiers Be Made Use Of in Vegan Formulations?

Yes, emulsifiers can be utilized in vegan solutions. Numerous plant-based emulsifiers, such as lecithin from soy or sunflower, supply efficient mixing without animal-derived components, making them ideal for a range of vegan products.

What Are Common Allergens in Emulsifiers?

Usual irritants in emulsifiers consist of soy, milk, and eggs, as particular emulsifiers are stemmed from these resources. Furthermore, some people may react to ingredients or preservatives used alongside emulsifiers in different formulas.

Exactly How Do Emulsifiers Impact Service Life of Products?

Emulsifiers enhance item stability by protecting against splitting up of ingredients, therefore expanding life span. They mitigate spoilage triggered by microbial growth and oxidation, causing long term quality and boosted top quality in numerous food and cosmetic formulations.

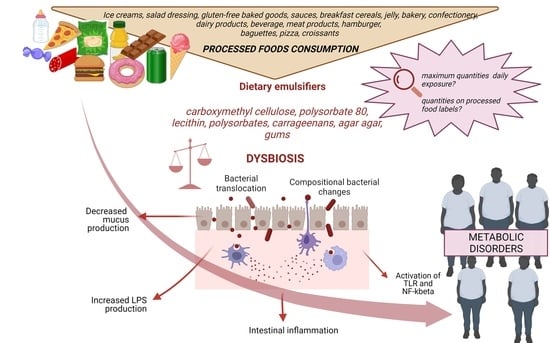

Are There Any Wellness Worries Related To Emulsifiers?

Research study shows potential health issues connected with emulsifiers, including digestive tract microbiome changes and this website swelling. While regulative bodies usually deem them secure, ongoing research studies continue to check out lasting impacts on health and wellness and general health.

Can Emulsifiers Improve Flavor or Scent in Formulations?

Emulsifiers can improve taste and scent in solutions by boosting active ingredient dispersion and security. This results in a more uniform product, allowing flavors to combine properly, ultimately causing an extra delightful sensory experience for consumers.

Emulsifiers might appear like a basic enhancement to formulations, they play an important function in stabilizing mixtures of ingredients that normally do not blend well, such as oil and water. In food solutions, emulsifiers help mix oil and water, creating smooth and uniform textures crucial for sauces, dressings, and milk products. Food-grade emulsifiers must comply with security laws, while aesthetic emulsifiers might require skin compatibility. Typical irritants in emulsifiers consist of soy, milk, and eggs, as particular emulsifiers are obtained from these sources. Emulsifiers can improve taste and scent in formulations by improving ingredient dispersion and security.